Feedback from CONEXPO – by Juho

March 31, 2011 | Posted by: admin | 0 Comments

Despite continued uncertainty in the U.S construction segment and in the overall economy, CONEXPO-CON/AGG attracted nearby 120 000 registered visitors. International registrants accounted for a record of 24 percent of the total, representing more than 150 countries. For CuproBraze Alliance, it was a great opportunity to see that even though the last years have been difficult, global construction industry is already looking into the future with reliant and positive prospects.

During the show, we witnessed a vast amount of new developments, in the areas like advanced diesel engines, RFID technology utilization in vehicle safety systems, and many other in vehicle, component and service businesses.

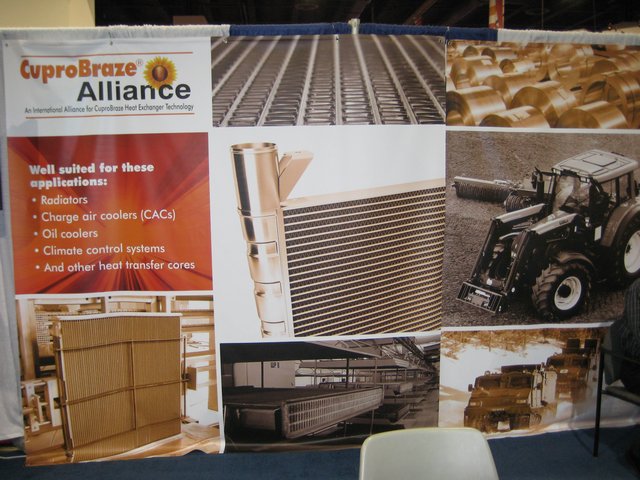

The message from CuproBraze Alliance to the visitors of our booth was to show the ways brazed copper-brass technology can support OEM’s, radiator repair shops and truck fleet owners both to higher productivity and to increased lifespan. Our visitors were very positive to what they saw and many of them already had discovered how CuproBraze technology could benefit them and their customers. On behalf of the CuproBraze Alliance, we would like to thank our visitors for their visits to our booth!

-

News Releases

- Reduction of Fan Power in Comparison to Plate and Bar Type Aluminum Heat Exchangers

- Cuprobraze Attending Aimex Exhibition

- Young Touchstone Leverages Benefits of Copper/Brass Brazing for Heavy-Duty Markets

- Bombardier Achieves Superior Performance at a Lower Initial Cost

- Blogs from 2011 – 2014 By Markku Ainali & Juho Partanen

Technical-Links

Testimonials

The advantages of CuproBraze over other heat exchanger technologies were clearly evident from the beginning.

Jorge Warnholtz Plant ManagerClimex WorldCuproBraze is the technology of choice for future generations of heat exchangers.

Jan AnderssonProject LeaderRabe ConsultingWe have successfully tested cooling systems with our customers and are now experiencing the initial waves of demand for CuproBraze.

Mike SprengerDirector of Sales & Marketing, Young Touchstone. ER 55The more familiar we become with brazed copper-brass, the more we like it.

Jack ChisenhallPresidentVintage AirAs a brazing process, CuproBraze can make heat exchangers that are inherently more durable than soldered copper-brass and also superior to aluminum products.

Randolph SinghChairman and Managing DirectorGS RadiatorsUsing CuproBraze technology, we can offer superior and cost-effective products.

- Sunil Haridass, DirectorDeccan Radiators & Pressings, Ltd.Clearly, it is superior to any prior technology. We firmly believe that eventually all charge air coolers will be made of copper and brass using the CuproBraze process.

Hannu VetikkoManaging DirectorFinnish Radiator Manufacturing CompanyIt is a milestone for Nanning Baling Technology to become the first company in China to mass produce CuproBraze heat exchangers.

Gu Yu, General ManagerNanning Bailing TechnologyAfter our specialists attended several seminars and visited SHAAZ’n new plant, it was obvious that CuproBraze was exactly what we needed.

Alexander Vedernikov Manager of Technical DevelopmentURALWe closely examined the CuproBraze technology and its implications for our markets. Our customers indicated that they would be interested in CuproBraze products if we could make them.

James E. CornwellVP of ManufacturingRADAC